EAW-52 V2 WBO2 and EGT display and controller

See

WBO2 wire-colors with

new wire-colors on page1 (old colors on page2; trivial to tell which one applies).

Wideband lamda sensor controller and display with internal EGT amplifier and display.

Mating sensor (

LSU4.9 or LSU4.2 sensor) is included when selecting the default option.

V2 has 6 more status-LEDs, more outputs and inputs than

VEMS Round WBO2 EGT.

The several extra features of RoundV2 make it capable to concurrently handle multiple control-loops (besides the WBO2 related control loops: boostcontrol or simple idle-control or even producer-gas reactor temperature control, gas-engine fuel-mixture lambda-control or island-mode RPM control):

- more analog inputs - useful for logging, or the control loops

- 3 power outputs with firmware support for (currently) 3 independent control loops (+WBO2 has additional power output and 2 control loops)

- more flashspace available for future firmware features

- 6 extra multicolor (red-green-yellow) status LEDs

Feedback signal for the 3 controllers can be:

- analog input (eg. boostcontol or temperature control, nonlinear inputs configurable with custom curve)

- wideband lambda value (mixture control eg. for wood-gas engines)

- RPM (idle control)

- EGT (K-thermocouple, eg. for gasifier bed-height control, output period up to 33 seconds suitable for auger-enable signal)

- Custom PWM command signal possibly from serial port via AIM-compatible sender like the VEMS v3.x ECU - besides displaying values measured directly or received from the engine control unit (like MAP, lambda, RPM, EGT ...) RoundV2 can be used to drive additional 5A outputs (12-14V by default, and max 40V if related protection diode is moved from the DSUB15 to the external device). Useful if more (than the onboard 30+ outputs of VEMS v3.x) outputs are required for a high-end V8 or V12 application.

Note: red-green display with black case is currently the default Case color can be any as long as it's black (sorry: more case color options might be available later).

Also

included :

- U-clamping

- connectors to make it work (WBO2 connector, supply, fuse)

Optional (but highly recommended):

LSU4 WBO2 sensor

Also optional:

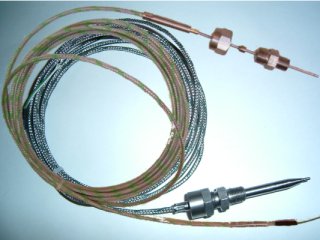

6mm conical or the 2 mm EGT (K-thermocouple with 2.5m cable) sensor is optional.

The 3mm sensor is very reliable, has high quality strain relief and 2m PTFE cable.

If you order with EGT sensor, the

K-thermocouple connector pair is INCLUDED

See also (related products, NOT included by default):

- USB to RS232 adapter cable (see Adapter cables)

- cable for EGT cable extension - normally not needed, because EGT cable is 2.5m long

- Request custom-specified WBO2 cable-length in the order comment for 5 EUR /meter * cablelength, (and expect +6..8 working days delay). Default is 1.5m+sensor cable (suitable for most installs). Sometimes dyno-operators request long WBO2 cable, upto 5 meter is recommended; some ordered with upto 10 meter long WBO2 and used it with perfect success (the max practical length possibly depends on local radio-interference along the cable-path).

Features:

- 3 digit 7 segment LED (with dots)

- 4 digit 7 segment LED (with dots)

- Voltage output. High resolution (up to 5V, 12bit, programmable output curve)

- RS232 level

- directly plugs into PC

- or USB-RS232 adapter

- or small dongle for CAN-physical layer bus (will not need to be removed from network even for firmware reflash)

- inputs and outputs related to supply and WBO2 and EGT measurement

- free outputs

- power

- signal level (external referenced voltage output)

- extra inputs

- button. Note: the "jetski" version has minor feature-deficit, most notably lacks the pushbutton (but it's filled with epoxi and somewhat more waterproof in several ways).

Firmware features

This is ment as an easy-to-use device, but quite a few advanced features are also supported.

- WBO2. real WBO2 control circuit (full implementation), not a fake value from narrowband voltage as most ledbar displays

- EGT (with cold-junction measurement)

- onboard-temp

- dimming

- display signal of RPM (frequency) input. Supports 0/5V HALL or optical sensor, or AC signal from variable reluctance (VR) sensor (1 bias resistor might be needed depending on the signal properties).

- high visibility display of any data coming from RS232 (eg. from genboard v3 controller or other ECU via AIM protocol)

- display the signal from 0-5V analog input with custom configurable curve

- 0-5V analog output. EGT signal, or WBO2 lambda/AFR signal with custom configurable curve (narrowband emulation also possible)

- Data can be logged to PC for further analysis

- The device can receive data via the RS232-DSUB9 port in "AIM" format, and display values with scaling (eg. from Celsius to Fahrenheit, km/h to mph conversion). See product page below for how to set up this. Note that the cheaper

Display-Only Round can also do this (that looks the same, but has only RS232 cable)

- firmware upgrade via bootloader (from command line or from

VemsTune

- Boostcontrol function (wastegate control via PWM-solenoid) is supported with RPM dependent target and reference-PWM values - simultaneously with WBO2 and EGT measurement

- Alternatively, instead of boostcontrol, idlecontrol or producer-gas mixture lambda control can be configured as well

- Idlecontrol uses the RPM input for feedback and controls a PWM-solenoid valve to feed air to an engine

- Producer gas mixture lambda control uses the wideband (LSU4 WBO2) sensor placed in the exhaust, and controls a 2-wire PWM idle-valve to feed air (usually there is a 1/2"-1" primary manual valve, and this smaller electric valve (eg. from a VW-passat gasoline engine) in parallel to it makes up for the variations (as the wood-gasifier internal conditions change over time, eg. temperature, moisture content, CO2 content). This function can be used to eliminate most of the manual tweaking the CHP (combined heat and power) powerplant otherwise requires to produce power/electricity (and heat), from woodchips or other suitable solid fuel. This feature is not currently available elsewhere, even for 3 times the cost of this device. If you need more outputs, or ignition control (and possibly injection for startup / backup / testing), check

the v3.x controller also supports this, and much more (eg. stepper-based idle control that can support much bigger valves with lower valve-power consumption).

RPM input (VR or HALL, several trigger-types) for display, logging, idlecontrol or boostcontrol. The RPM input frequency detection is very precise

For any warranty issues checkout Repair/Upgrade, see Shipping and Returns.